The faucet is no stranger to everyone and is an indispensable product for every family. So how is the faucet made? What is its production process and internal structure? Are you also very curious, then through this article to answer in detail, I believe you will gain something after reading it.

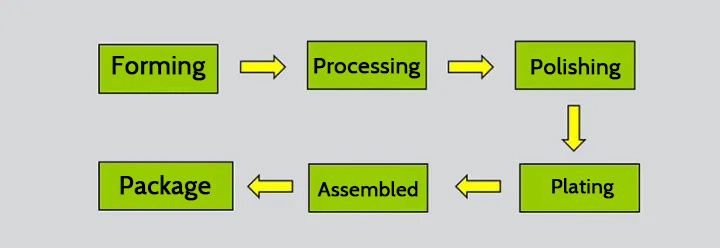

The function of the faucet is to control the water output, but in order to meet the preferences of consumers, there are various shapes and designs, but no matter what shape the faucet is, from raw materials to finished products, it needs to be formed, processed, polished, electroplated, assembled, and packaged. every process, and every process in it cannot be ignored.

1. Sand core.

What is a sand core? The sand core can be simply understood as the space through which water flows inside the faucet. It is punched by a machine, and then the excess sand is cut off, so as not to affect the effect of the faucet molding.

2.casting,

We put the sand core into the machine.Then start pouring copper water. The copper water is filled along the sand core. After the copper water is cooled and formed, it is taken out. The sand core in the copper body is loosened into sand, and then flows out to obtain the faucet shells to be processed.There is still a gap between these newly formed faucet shells and the shape of the faucet we have seen. It is necessary to cut off the excess copper around the periphery to obtain the basic shape.

3.polishing

Polishing is an important step before electroplating. It is related to the flatness of the surface of the coating, just like human skin. If the surface is uneven, it is impossible to flatten the skin after applying makeup. Therefore, the uneven coating of the faucet is not necessarily a problem with the electroplating. More than a dozen polishing processes, with different requirements, take turns, and finally the dull and rough surface of the faucet is polished to be smooth and delicate.

4: Plating

After the faucet is polished, the surface is only flat. If you want to be smoother and add other colors, you need to go through the process of electroplating. There are various processes and colors for electroplating. First, hang the polished faucets on the machine one by one, then put them into water, and degrease them by ultrasonic to remove the impurities and dust on the surface of the faucet. Then start to paint the desired color. After plating, drying and inspection.

5.Assembly and Inspection

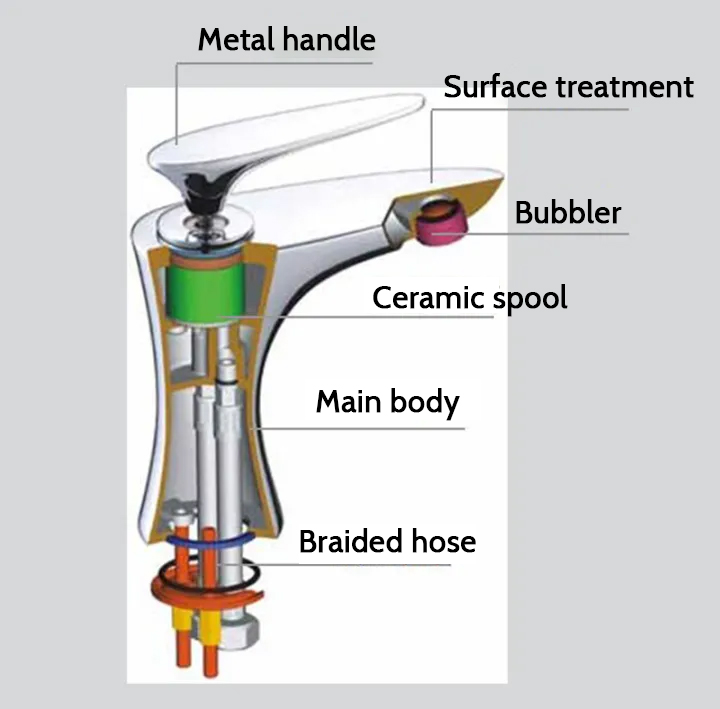

Assembly is the process of assembling the faucet body and all the accessories together. After the faucet is installed in the valve core, it is necessary to test the air and water. The purpose is to check whether there is air leakage or water leakage. If any problem is found, it will be scrapped immediately. All product of HEMOON is After layers of checks before leaving the factory, choosing HEMOON is choosing guarantee.

Post time: Nov-15-2022